*** Final Report ***

HI-1064 McDonnell Douglas MD80 Miami Florida 21 JUN 2022

4 Minor & 136 No Injuries

Pilot Flight Time:

Captain – 14388 hours (Total, all aircraft), 1400 hours (Total, this make and model)

First Officer – 822 hours (Total, all aircraft), 269 hours (Total, this make and model)

On June 21, 2022, about 1738 eastern daylight time, RED Air flight 203, a Boeing MD-82, HI 1064, overran the end of runway 9 at Miami International Airport (MIA), Miami, Florida, after the left main landing gear (MLG) failed shortly after landing. The airplane impacted a concrete and steel structure in the grassy area to the left of the runway and came a stop shortly afterward. A postcrash fire ensued while the airplane was being evacuated. Of the 140 occupants aboard the airplane, 4 passengers sustained minor injuries. The postcrash fire was subsequently extinguished by aircraft rescue and firefighting (ARFF) personnel from Miami-Dade Fire Rescue. The airplane was operating under Title 14 Code of Federal Regulations Part 129 as a scheduled international passenger flight from Las Américas International Airport (SDQ), Santo Domingo, Dominican Republic, to MIA.

The flight crew arrived at MIA about 0830 for the first flight of the day, from MIA to SDQ. The first officer conducted a walkaround of the airplane and observed no anomalies. The airplane departed MIA about 1028 and arrived at SDQ about 1115. The accident flight departed SDQ about 1435. The captain was the pilot monitoring, and the first officer was the pilot flying.

The takeoff, climb, and en route phases of flight were uneventful. The flight was cleared for the instrument landing system approach to runway 9, and the flight crew stated that the approach was normal. The first officer disconnected the autopilot when the airplane was descending from 400 to 200 ft above ground level and then manually flew the airplane for the remainder of the flight.

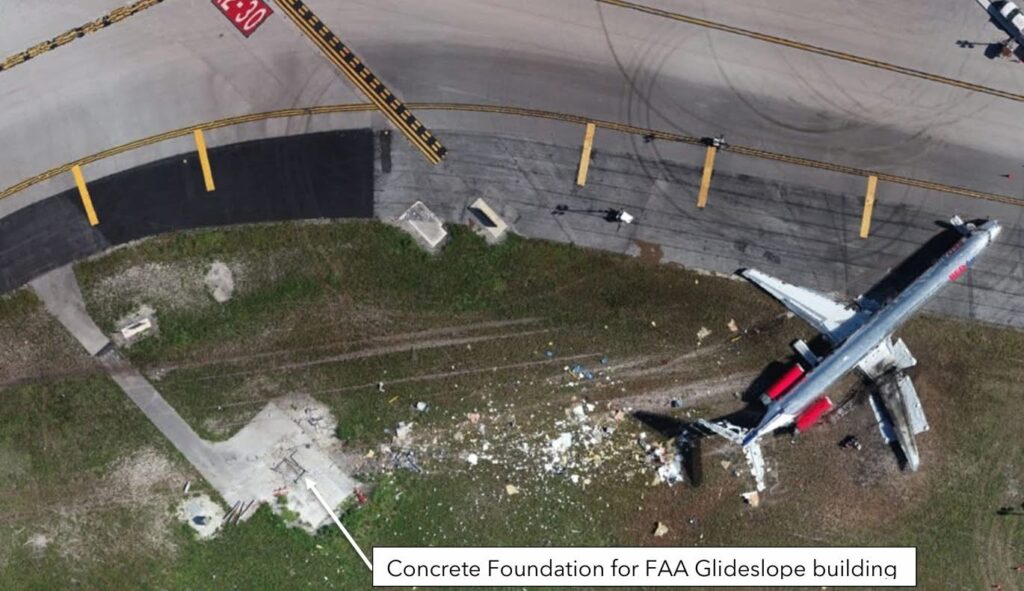

The first officer recalled that the airplane touched down smoothly on the right and then the left MLG and that the airplane was slightly to the right of the centerline, which he corrected after touching down. Shortly afterward, the flight crew felt a vibration on the left side of the airplane. The vibration increased, and the airplane veered to the left despite the crew’s efforts to maintain the airplane on the runway centerline. The airplane subsequently departed the paved runway surface and impacted the glideslope equipment building for runway 30, which was located to the left of runway 9, causing the nose landing gear and the right MLG to collapse. A postcrash fire began on the right wing after the fuel tank on that wing was breached, after which the airplane came to a stop.

The flight attendants described the flight as “calm” and “normal” with some slight turbulence during the descent. The flight attendants reported that the initial touchdown was smooth but that, once the thrust reversers were activated (which they stated was “quicker than normal”), they felt vibrations and noted that it was “very loud” inside the cabin. The thrust reversers were suddenly “turned off,” which was followed by vibrations that were “very excessive,” and everything inside the cabin was “shaking violently.” The flight attendants realized that something was wrong and instructed passengers to remain seated and put their heads down. The airplane started “sinking on the left side,” and then the airplane stopped completely.

The flight crew initially instructed the passengers to remain seated. While performing the engine shutdown checklist, the crew learned, from the lead flight attendant, about smoke in the cabin, so the captain immediately commanded a passenger evacuation from the left side of the airplane, and the crew began performing the evacuation checklist. The evacuation and emergency response are discussed in the Survival Aspects section of this report. (As discussed in the evacuation information, one of the aft flight attendants had initiated the evacuation before the captain’s command.)

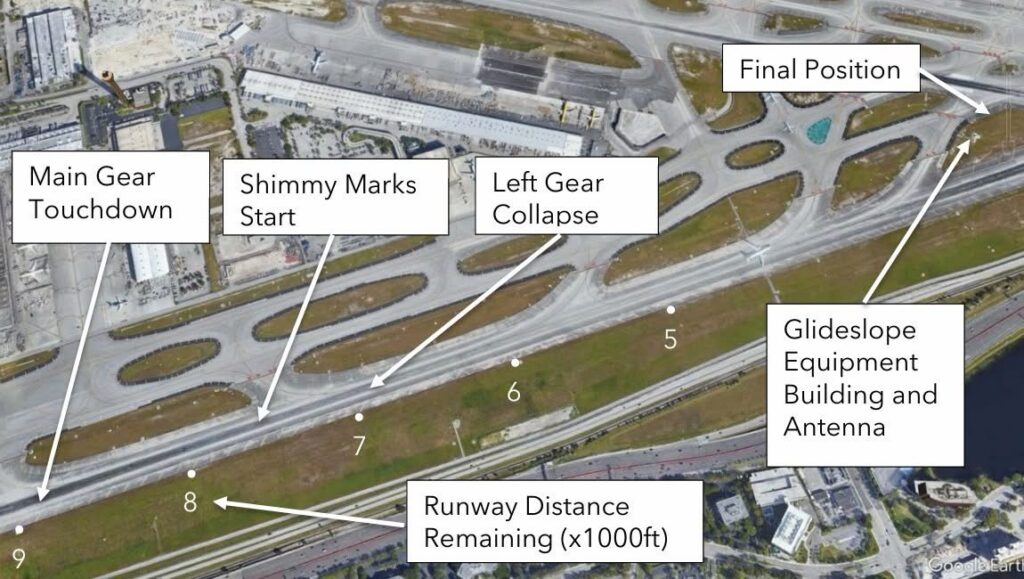

Video evidence (from an airport camera and a passenger’s cell phone) showed that the airplane touched down on runway 9 with about 8,900 ft remaining. Tire deposits on the runway, which started about 1,300 ft from the touchdown point, showed evidence of left MLG shimmy, which is a torsional vibration mode of the landing gear in which the inner cylinder oscillates relative to the outer cylinder. The amplitude of the shimmy increased steadily until the left MLG collapsed under the airplane with about 6,930 ft remaining on the runway. The airplane skidded on its left wing down the runway, veered to the left, and the right wing impacted a glideslope equipment building and antenna. The airplane’s nose gear and right MLG collapsed, and the airplane came to a stop. Figure 3 shows pertinent events during the accident landing.

Maintenance Program:

The RED Air DC-9-82 maintenance program was approved by the Dominican Republic Civil Aviation Authority, the Instituto Dominicano de Aviacion Civil. The program was derived from several Boeing DC-9-82 documents and the Pratt JT8D-200 engine maintenance program. The RED Air maintenance program manual referenced FAA airworthiness directives for the DC-9 82. Review of the airplane’s logbook (specifically, entries that were dated from March 21 to June 21, 2022) revealed normal routine maintenance/servicing of the airplane and no discrepancies or chronic issues with the landing gear. During a follow up visit to RED Air, additional documents were presented and showed a record of non-routine maintenance conducted where the left shimmy damper reservoir fluid level was low and it was refilled with hydraulic fluid.

The airplane’s landing gear were overhauled by Suncoast Landing Systems, Medley, Florida, in August 2016. RED Air records showed that the left MLG had accumulated 35,405 cycles at the time of overhaul and that the next overhaul was due on August 3, 2026, or when the gear had accumulated 55,405 cycles, whichever came first.

According to the Boeing MD-80 Maintenance Planning Document, the airplane’s nose and main gear wheel wells, which included the shimmy dampers, were required to be visually checked every 3 days for condition, security, and proper servicing. The RED Air maintenance program included a shimmy damper check during the airplane’s “S” service, which consisted of a walk-round inspection of the airplane to examine the condition and security of various components, look for discrepancies, and review the maintenance logbook. The “S” service on the accident airplane was last accomplished on the day before the accident (June 20, 2022). Maintenance records showed no anomalies concerning the last shimmy damper check.

Weather:

At 1753 (about 15 minutes after the accident), the MIA automated surface observing system reported wind from 050° at 9 knots gusting to 16 knots, visibility of 10 statute miles or greater, a few clouds at 3,000 ft above ground level (agl), a few clouds at 4,500 ft agl, broken ceiling at 25,000 ft agl, temperature of 30°C, dew point temperature of 16°C, and altimeter setting of 30.08 inches of mercury.

MIA is located about 8 miles northwest of Miami, Florida. Runway 9/27 was constructed of grooved asphalt and was 13,016 ft long and 150 ft wide. The landing distance available was 11,397 ft.

Wreckage:

The airplane was found resting on its fuselage with all landing gear collapsed. The L1 and L2 doors were opened with their evacuation slides fully inflated. The forward right overwing window exit and both left overwing window exits were opened. The R1 door, tailcone, and aft right overwing window exits were not opened.

The interior of the cabin was generally intact. The main aisle and areas leading to the floor level exits were primarily clear with no visible buckling of the floor structure. The area near the overwing exits contained personal items (such as glasses, jackets, and baggage). The forward right overwing exit hatch was found on the cabin floor leaning against the seatbacks forward of the exit. One left overwing exit hatch was found on the trailing edge of the left wing, and the other left overwing hatch was found on the cabin floor.

Rubber deposits from the left MLG tires were found on the runway. These deposits grew in amplitude, indicating an increasing shimmy. The initial markings were continuous and were consistent with side-to-side oscillations. The markings became more arched and noncontinuous, consistent with the axle/wheels turning about the vertical axis. The markings then changed from a two-tire pattern to a single-tire pattern and were located on the opposite side of the runway centerline, consistent with the tire sidewall contacting the runway after the left MLG collapsed. The first debris located on the runway (about 1,840 ft from the touchdown point and with 7,060 ft of runway remaining) was a small piece of rubber that was later determined to be from the outboard side of the No. 2 tire.

Analysis:

The collapse of the left main landing gear during the landing roll resulted in a runway excursion due to a loss of controllability on the runway, during which the aircraft impacted a small equipment building, breaching the right-wing fuel tank and causing a post-crash fire. The performance of the crew was thoroughly evaluated during this investigation and found to be appropriate for the circumstances of the accident.

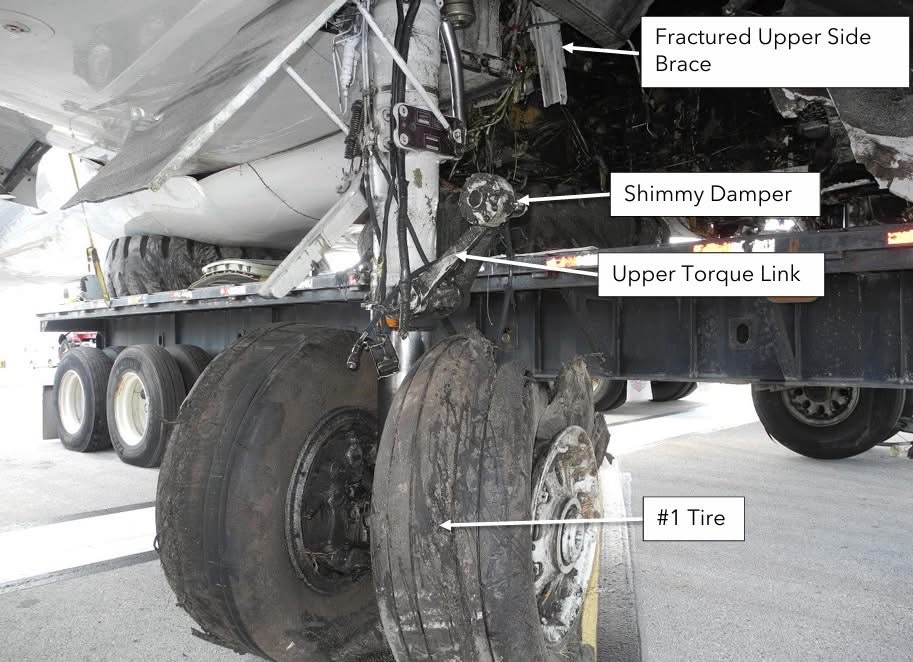

The focus of this analysis is the cause of the left main landing gear collapse. Particularly (1) the left shimmy damper’s failure to adequately dampen vibration during landing and (2) the failure of the left main gear downlock mechanism due to excessive vibration. Figure 1 is a representation of how vibrations are typically dampened by a fully functioning shimmy damper. Figure 2 shows the rubber tire transfer markings that indicate the left main landing gear was shimmying down the runway.

The left shimmy damper was examined and found to be assembled correctly. However, the check valve was found to be leaking and the cap for the check valve service port was missing. The damper requires sufficient hydraulic fluid to adequately dampen normal vibrations in the system. For a significant amount of fluid to leave the damper, there would have to be failure of both the check valve and the cap for the service port.

If the leak in the check valve existed prior to the accident flight, there was potential for it to be discovered by maintenance when servicing the shimmy damper with hydraulic fluid. When a damper is serviced, documentation of that service must be made in the maintenance logs. The investigation’s review of maintenance logs revealed that the last time the left shimmy damper was serviced was in June of 2021, 12 months prior to the accident.

Damage to check valves typically occur during servicing and any leaks would occur following a servicing event. Considering the last documented servicing of the shimmy damper occurred 1 year prior to the accident, it is likely that the check valve leak had silently developed and was sitting latent until a problem with the service port cap occurred.

The shimmy damper was checked the day before the accident per the “S” check. There was no record of the damper being serviced during this “S” check suggesting that the service port cap was present and hydraulic fluid levels were above minimums. Therefore, the investigation deduced that the cap went missing or was compromised at some point in the 2 flights and 24 hours between the last “S” check and the accident touchdown. After the service port cap failed, sufficient fluid likely leaked from the damper through the leaking check valve and the uncovered service port in the hours prior to the accident, ultimately compromising the functionality of the shimmy damper.

Unfortunately, the physical breach of the reservoir inflicted during the gear collapse resulted in the release of hydraulic fluid and precluded evaluation of whether the damper was properly serviced. This limited the investigation’s ability to definitively determine the root causes behind the apparent check valve and service port cap failure. The investigation explored potential contributions of operator organizational oversight and regulatory oversight of operator’s maintenance, however insufficient evidence existed to establish a direct link between any of these factors and the accident.

Facing severe undampened axial vibration on rollout, the left main gear lower torque link (downlock) failed due to overload. When the downlock failed, the side braces were free to, and did, fold in the opposite direction from normal as the gear folded inboard and collapsed.

Probable Cause and Findings:

The structural failure of the left main landing gear downlock following ineffective shimmy dampening during the landing roll which caused the collapse of the left main landing gear, resulting in a runway excursion and post-flight fire.